Description

Product Description:

The MAGFLO™ EV15 Vacuum Relief Valve is designed to protect water heaters, containers, and steam systems from vacuum conditions that can cause damage. By allowing air to enter the system, this valve prevents the siphoning of water and the potential collapse of tanks or water heaters due to negative pressure.

Key Features & Benefits:

- Versatile Application:

Ideal for use with all types of water heaters, containers, and steam systems. - Automatic Air Intake:

Prevents vacuum conditions by automatically permitting air to enter the system. - Low-Profile Design:

Features a compact design for easy and convenient installation. - Reliable Protection:

Helps avoid damage and system failures caused by pressure imbalances.

Pressure & Temperature Specifications:

- Max. Working Pressure: 200 psi (1400 kPa)

- Max. Working Steam Pressure: 15 psi (105 kPa)

- Max. Working Temperature: 110°C

- Vacuum Rating: ≤ -0.0034 MPa

- Venting Capacity: 1.55 L/s

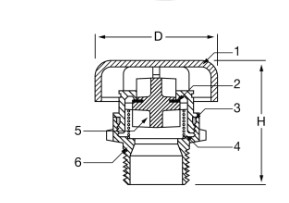

Weight & Dimensions

- Size: 1/2″

- Connection: 1/2″ MNPT

- DxH mm: 50 x 50

- Weight: 101 grams

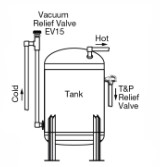

Typical Installation:

The EV15 Vacuum Relief Valve should be installed at the highest point of the cold water inlet. It must be positioned vertically in an upright orientation. Ensure that no valves are placed between the relief valve and the tank. Proper installation is crucial to ensure optimal performance and protection.

Applications:

- Water Heaters: Protects residential and commercial water heaters from vacuum conditions that can lead to tank collapse or damage.

- Industrial Containers: Suitable for various types of industrial containers to prevent vacuum-induced damage and maintain system integrity.

- Steam Systems: Ensures the safe operation of steam systems by preventing negative pressure conditions that could cause system failures.

- Boiler Systems: Ideal for use in boilers to safeguard against vacuum conditions that might lead to structural issues or operational disruptions.

- Piping Systems: Effective in piping systems where vacuum relief is necessary to prevent damage to pipes and associated components.

- HVAC Systems: Useful in HVAC systems to maintain proper pressure and prevent potential damage due to negative pressure conditions.

Note: Download the tech sheet for detailed illustrations showing typical and correct installation positions.